Plastic molding

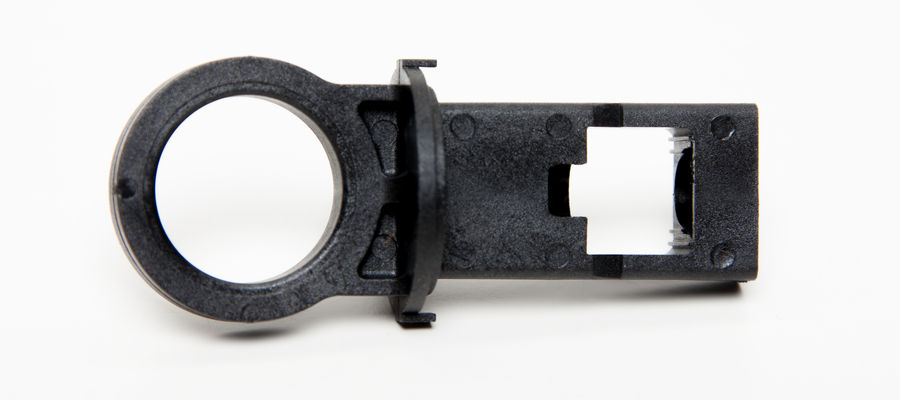

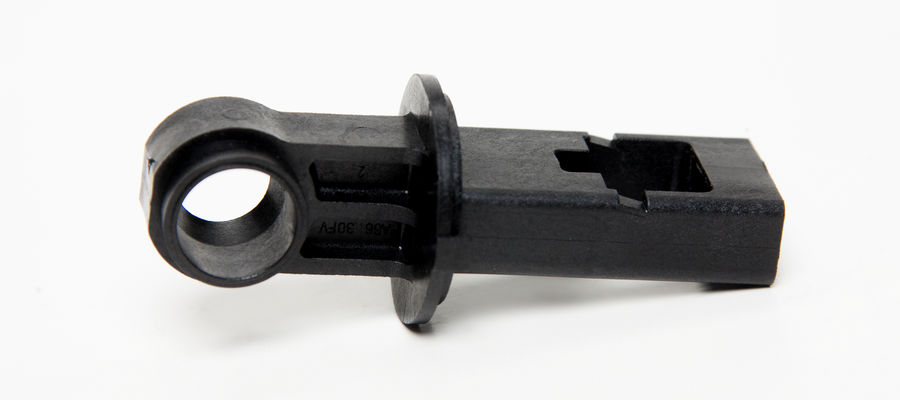

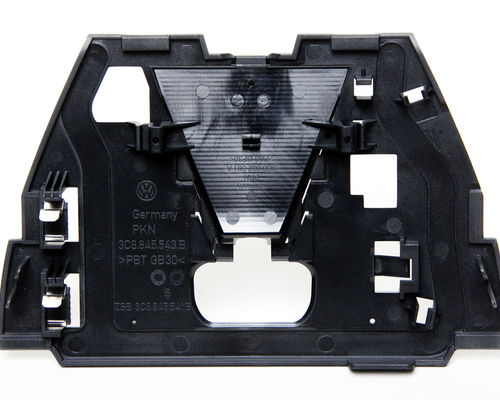

For mounting inhouse or as a single item supplied, we produce length adjusters from various glass fiber reinforced materials. We also produce protective covers individual components in the vehicle and unreinforcerd components of various sizes.

We produce small series through to permanent mass together in consultation with our customers.

Mounting assemblies and small systems

We assemble inhouse all possible assemblies up to small system. In various methods we use your plastic parts, put them together perfectly and deliver this ready to use.

Our methods are:

- Bonding of plastic parts with 2k adhesive, as well as PURE by special devices

- Crimp terminals for the MAN and Volvo Truck

- Installation of lacquered visible parts in the automotive industry